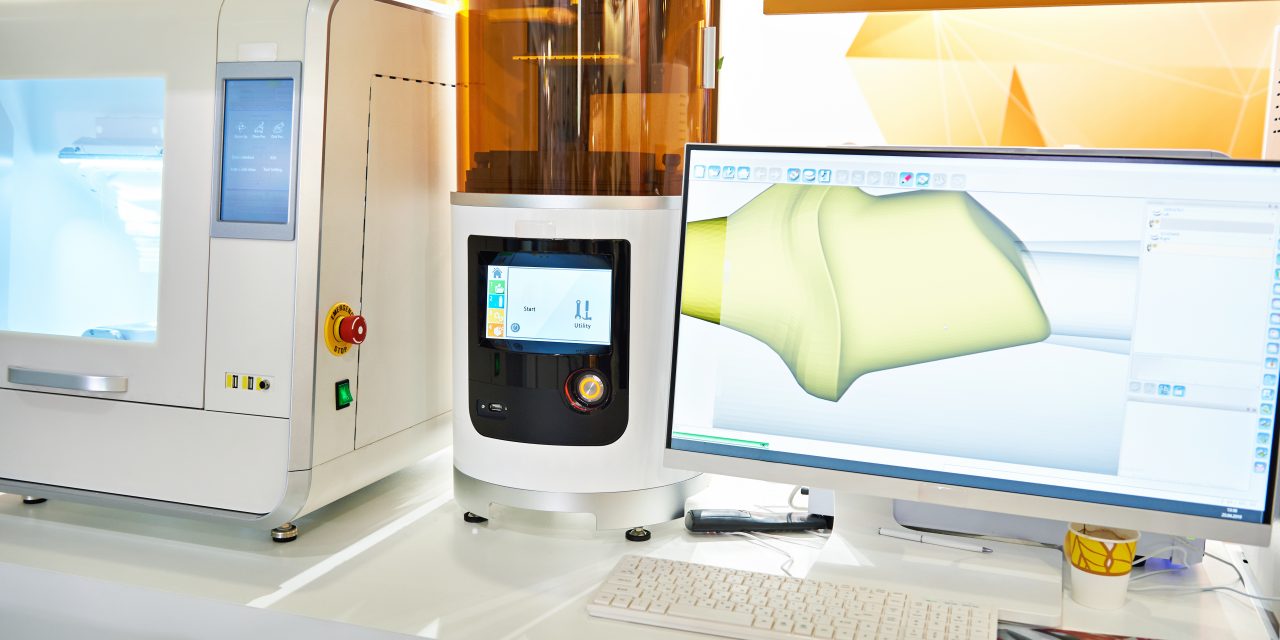

Production concept options for CAD/CAM digital dentistryĭigital dentistry permits multiple avenues for creating a restoration with CAD/CAM technology. The milling device / production technology makes up the computer-aided manufacturing element of CAD/CAM, and completes the entire process by creating the prosthesis based on the processed digital scan data.

CAD CAM IN DENTISTRY SOFTWARE

This scan is then processed by a software that creates a data output of the prosthetic design to be milled. The digitalization tool / scanner is responsible for taking the intraoral scan, which allows the dentist to digitally map out the topography of the patient’s intraoral environment. The CAD/CAM system is made up of three components: the digitalization tool / scanner, the processing software, and the milling device / production technology that creates the final product. This minimally invasive method also allows for the patient to pay only a single visit to the dentist and undergo a procedure that is far more comfortable, quick and painless than the conventional impression.

polyvinyl siloxanes, polyethers and hybrids), and potential lost time from work and multiple sessions of anaesthesia.ĭigital impression taking, on the other hand, allows the dentist to take an intraoral scan of the patient’s mouth and create a customized implant based on the scan, with the final restoration having exceptional aesthetic, fit and longevity. The conventional method of taking impressions also is taxing on the patient, who must sit through multiple visits, poorly fitting trays being placed in the mouth with unpleasant textures and flavors from the impression materials (e.g. Conventional elastomeric impression taking, by nature, is more prone to error due to the various steps and visits involved in the process, as well as the number of professionals that are required to complete a single restoration.

This digital form of dentistry is a world apart from the conventional method of taking impressions. Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) uses computer software to design and manufacture the implant prosthesis.

The digital age of implant dentistry is upon us and CAD/CAM technology aids dentists in making a superior prosthesis for their patients.

0 kommentar(er)

0 kommentar(er)